0

(pusty)

0

(pusty)

Twój koszyk

Brak produktów

Zobacz większe

Zobacz większe

32960055957

Nowy produkt

35,88 zł

Note:

1. Due to the light and screen difference, the item\'s color may be slightly different from the pictures.

2. Please allow 0.5-2 cm differences due to manual measurement.

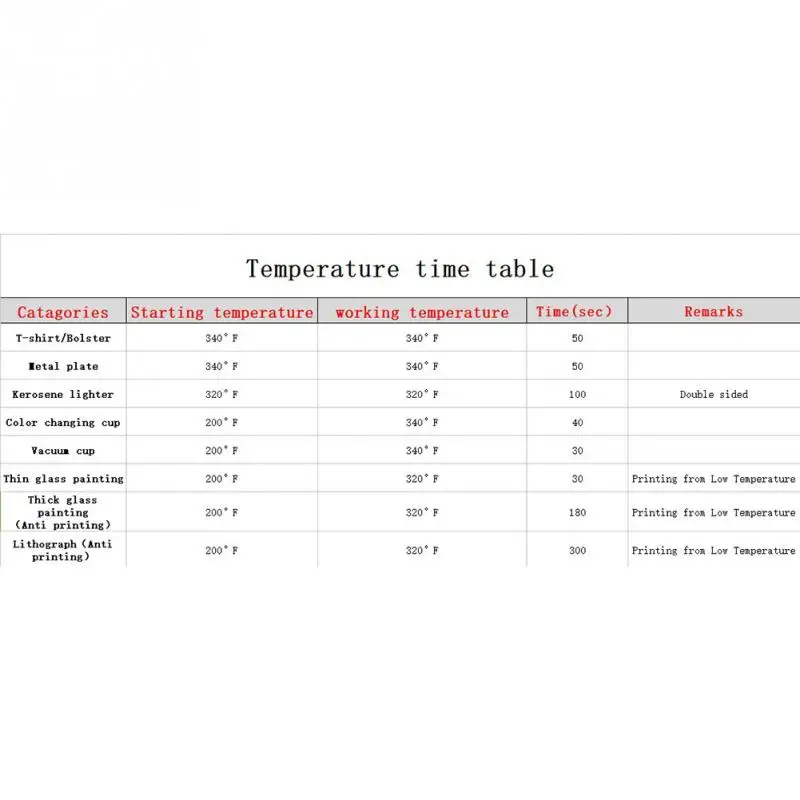

Main uses:mainly used in non-cotton light color clothes (chemical fiber, polyester, jersey fabrics), including coated cups, plates, hats, metal, glass,slate painting, wood, key rings, cosmetic mirror and other item.No feel, transfer color bright, color reduction is good.

Usage:The pattern is printed on the sticky side. When the pattern is printed, be sure to wait for the pattern to dry before transferring.

Ways to distinguish pros and cons:

1.Dip some water in your hand, which is slightly wet, and then pinch both sides of the paper with your hand. The sticky side is the printing side;

2.Take out the paper, print the front and back first, and print the clear side of the pattern.

3.A simple way to distinguish the front and back of paper:rough surface for the printing surface, smooth surface for the back.· because the paper surface has layers, it will be slightly preheated, and the paper will be bent back before printing and then put into it for printing. Slow drying sublimation paper paper needs layers, is used to prevent ink from directly contact with the paper to prevent ink from being absorbed by the paper), in order to achieve the ink on the paper more fully transferred to the transfer of objects to achieve the color than other paper more bright effect. Good hot stamping effect, paper ink quality plays a crucial role in the decision.

Special note: because the sublimation paper is slowly dry, the surface has a special layer of coating, resulting in ink can not be quickly absorbed by the paper, so that the color of the transfer than the ordinary color jet paper bright color, transfer rate is complete. But at the same time will lead to the printer in the printing time there is gear printing, the larger the number of printing, the deeper the gear printing, the solution is generally to use a cotton swab to dip alcohol to clean the gear, or in the printing time to the cool air at the paper inlet, which can slightly reduce gear marks, but cannot eliminate them.If you are new to sublimation paper, please note that this is a property of sublimation paper, not a quality problem.Please bear the freight for return and replacement.

Reviews (8)

Reviews (8)